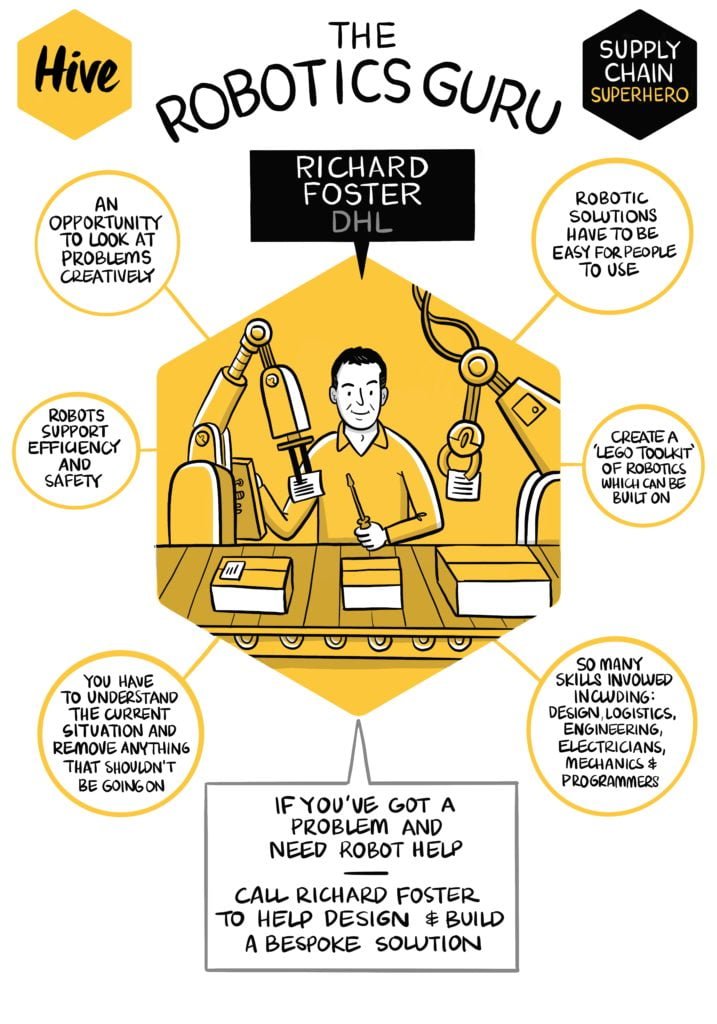

The Robotics Guru

Why is robotics so important to supply chains right now?

There are a number of different reasons. Traditionally, robotics has been focussed on efficiency, they let us use our people to the best of their ability, not just asking them to move a box from point A to point B. The health and safety aspect is increasingly important as well, and staff welfare not having to perform heavy or repetitive tasks over and over again. There’s also an aspect of staff development and building new skills.

What does your department do?

Our department was founded four years ago as an internal startup and it’s snowballed from there. The robotic systems we’ve been deploying recently could have handled anything from your advent calendars to your covid tests. There are so many different areas we touch and we have an opportunity to be creative in terms of how to solve the problems we face. We do a lot of research and development where we work, which makes it really interesting.

Tell us about how you approach the problems you face

First we have to understand and analyse the current situation and work out exactly what can be improved. In fact, the first thing is to remove anything which shouldn’t be happening, then improve remaining processes and only then should you look to automate. We take an incremental approach, we might only automate 20%, but we create modular systems which can be built on. We also use collaborative robots with a really small footprint which work with our teams.

How do you think robotics will change over the next few years?

I think prediction, AI, will be the most transformative thing to affect the industry next. Once that becomes mainstream it will be a gamechanger because things we wouldn’t consider now will become affordable and it’ll change the way we work. But if you look at how robotics has evolved even over the last four years it’s transformed the way we work. Technology is moving so fast, people will evolve with the industry.

What roles should anyone interested in robotics look for?

We used to think we needed one person to deliver everything, but actually we need a lot of different skills. Analytics and programmers, graphic designers to

help design the parts which we 3D print. Electricians, engineers and mechanics to build the machines and keep them running. There are a lot of different routes into robotics.

What’s your best advice for anyone wanting to get into robotics now?

Learn how to take things apart and put them back together. Those are the kind of people we want. What the industry needs is people who aren’t afraid to fail, or to make a step change in automation. We’re doing some very fast paced research and development because we’re involved in problem solving, you need a fearless attitude. In supply chain there’s more and more automation coming in and you need to understand how it works. If you don’t understand it you’re going to be left behind.