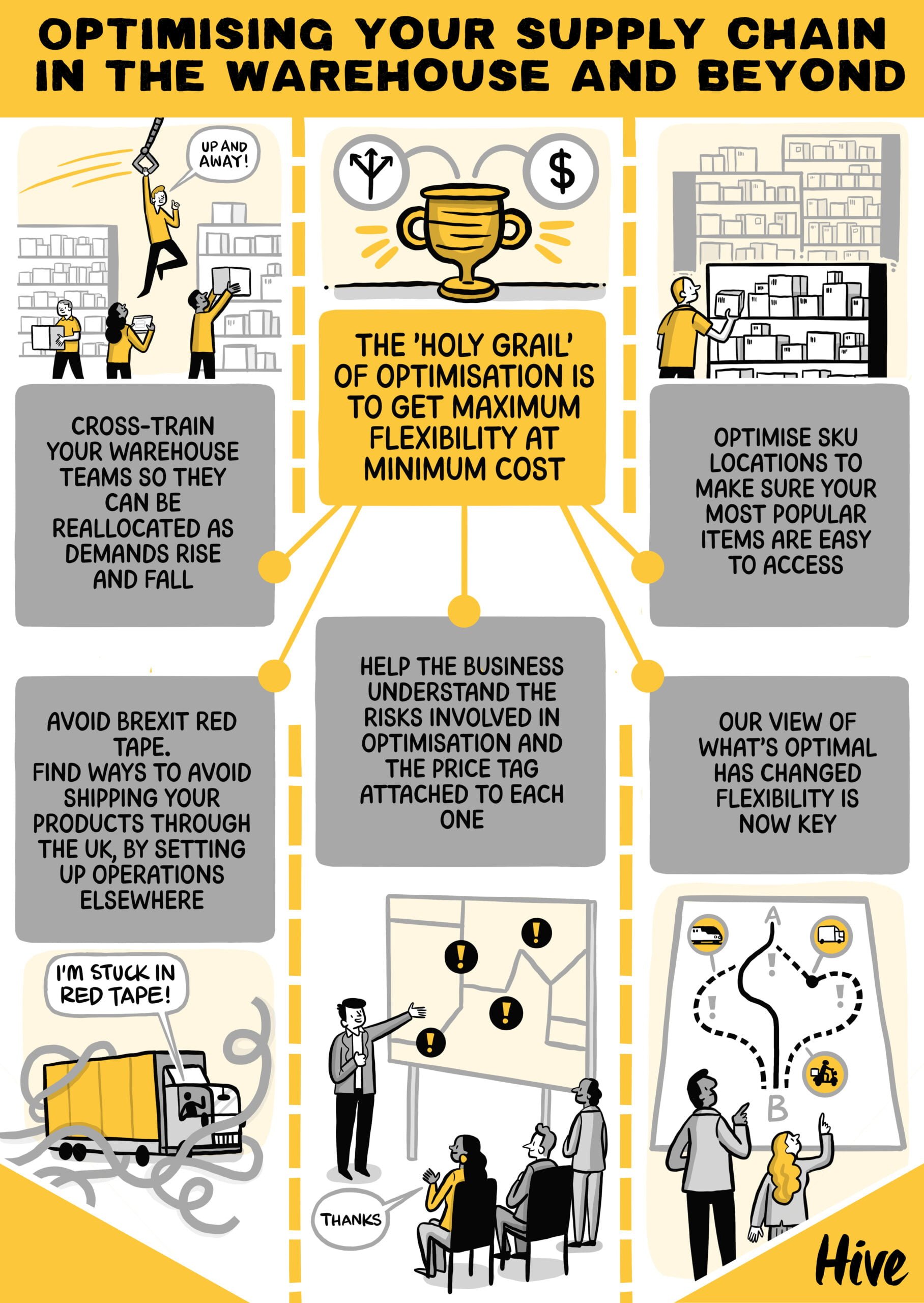

It’s not about cost anymore:

Optimising supply chains in today’s complex environment requires a delicate balance of cost efficiency, flexibility, and resilience. Companies must stay customer-focused, adapt to post-COVID realities, and navigate the challenges of Brexit, wars and shipping disruption. Leveraging technology, streamlining operations, and engaging staff are crucial for achieving supply chain excellence

In a nutshell…

- Optimisation encompasses both efficiency and flexibility: everyone accepts that ‘unpredictable’ events do happen now.

- Brexit has introduced significant challenges, particularly regarding border crossings and regulatory uncertainty.

- Employee engagement is crucial for identifying optimisation solutions and driving operational improvements.

- Managing SKU complexity and space utilisation remains a persistent challenge, complicated by legacy infrastructure.

- Balancing resilience and cost is paramount, highlighting the need for a nuanced approach to optimisation strategies.

A closer look…

Optimisation in action

The pandemic has highlighted the importance of space utilisation. For some businesses, order numbers surged during COVID-19, but have now returned to pre-pandemic levels—with more traditional peaks throughout the year. Whilst efficient space management to ride out extreme circumstances and the subsequent levelling off of orders is posing a headache, it’s vital to get right.

Evaluating the benefits of ‘own’ warehousing vs. outsourcing is essential for balancing costs and innovation. The level of upfront investment and potential cost savings from innovation must be balanced against the need to control and manage your own space. Members looking to find a new balance and manage multiple buildings must weigh the costs of maintaining vs. dilapidating infrastructure.

The consolidation and streamlining of 3PL operations is also important for reducing costs. Regular 3PL reviews and tenders (every two years has been flagged as best practice) ensure service providers remain accountable, but this process is resource-intensive, requiring dedicated personnel. Finding the balance is something many retailers are struggling with.

The role of technology is, unsurprisingly, growing in supply chain optimisation. For many members, implementing a new WMS can provide comprehensive visibility across the entire stock profile, enabling better in-house management. Voice picking technology is being implemented by several members and offers potential cost savings and efficiency improvements. While there are concerns surrounding accent recognition, modern systems have shown remarkable adaptability, making them a viable option for seasonal and international workforces.

Finally, optimising SKU locations and inventory management is critical. For instance, tailoring product placement to maximise space utilisation, such as creating dedicated pick spaces for fast-moving SKUs, can significantly enhance efficiency. Regular reviews and adjustments to product mixes have been proven to improve damage rates and operational efficiency.

Still to do…

Brexit continues to pose challenges for cross-border operations and often dominates discussions around optimisation as it poses a blocker to many plans. Companies are having to navigate new regulations and paperwork, often needing to employ specialised staff to manage these requirements.

Dealing with the complexity of SKU management, especially when expanding into new markets, remains a challenge. Companies must find ways to manage the segregation and differentiation of products for various regions, taking into account different languages and packaging requirements, as well as legal expectations and different systems.

Overall, there’s a need to balance optimisation with flexibility and adaptability. The pandemic, the Suez canal crisis, Brexit and ongoing issues around the war in Ukraine have underscored the importance of resilience, showing that overly rigid supply chains can be vulnerable to disruptions. Instead of focusing solely on just-in-time models, members are now considering how to bake in flexibility to adapt to unforeseen events—and learning how to present these contingency plans to senior management.