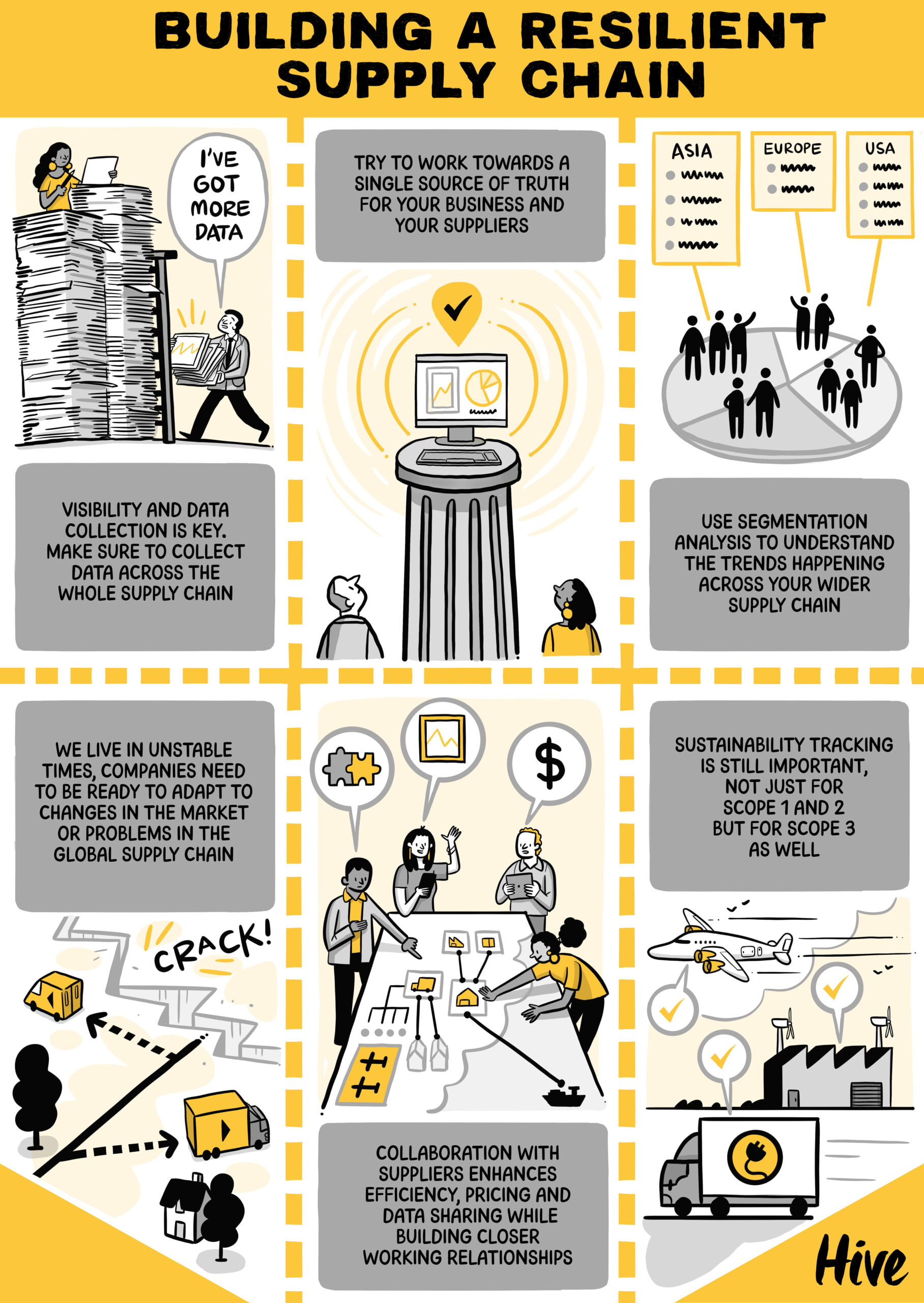

Building resilient supply chains:

Resilient supply chains are crucial in today’s disruptive environment. Enhancing visibility and collaboration with suppliers, accurate data collection, and sustainability tracking are key strategies. Companies must adapt and innovate to maintain efficient and sustainable operations

In a nutshell…

- Supplier portals are essential for modern supply chain management.

- Data visibility and accurate data collection are crucial.

- Supplier segmentation analysis improves resilience.

- Sustainability tracking is becoming increasingly important.

- Collaboration with suppliers enhances efficiency.

- Adapting to disruptive environments requires innovative strategies.

- Aligning systems for end-to-end visibility is key.

A closer look…

Resilient supply chains in action

The disruption of recent years has underscored the importance of building resilient supply chains. Key to this resilience is the adoption of advanced supplier portals, which enhance visibility and facilitate collaboration.

Accurate data collection and segmentation analysis of suppliers are both critical for effective resilience planning. For example, one senior member implemented a supplier compliance onboarding process to ensure suppliers understand the importance of packaging, paperwork, and product safety. This initiative not only improved compliance, but also strengthened relationships with suppliers.

In a disruptive environment, companies have had to innovate and adapt. Many businesses faced challenges with integration between Warehouse Management Systems (WMS) and Enterprise Resource Planning (ERP), leading to visibility issues.

Addressing this, members are now focused on consolidating their systems into a single platform to visualise and customise information. This integration facilitates better scenario planning and improves overall efficiency, although it is recognised that there is no one-size-fits-all solution, and complexity increases with the scale of the business.

Sustainability is another crucial aspect of resilient supply chains. Accurate tracking of sustainability metrics is essential as consumers demand more eco-friendly practices. However, transparency in the logistics chain, such as differentiating between petrol and electric vehicles, remains a challenge. Retailers must be transparent about their sustainability efforts, and supplier portals can play a vital role by centralising data and improving traceability.

Still to do…

Moving forward, companies must continue to enhance their collaboration with suppliers through advanced supplier portals. Portals should serve not only the needs of retailers, but also provide value to suppliers, such as visibility into deliveries and invoice management. Implementing a supplier portal in phases allows for gradual adaptation and customisation to meet both parties’ needs.

Addressing the challenges of data visibility and accurate collection is still ongoing. Retailers need to integrate various systems to ensure end-to-end compliance and streamline operations. Although it’s expensive, this integration offers significant benefits when it comes to providing a comprehensive view of the supply chain.

Another important ‘to do’ is the localisation of supply chains for each market and region for managing diverse regulatory requirements and ensuring timely product delivery. The shift towards onshoring, especially in regions like the US, is becoming more attractive due to the complexities and risks associated with international shipping.

Resilience planning remains a top priority. Companies need to continually budget and re-budget their freight, adapting to the ever-changing landscape. Understanding and mitigating risks through better data and system integration will be key to maintaining a competitive edge.